Last Updated on 23/08/2020 by Piero Mattirolo

The specific methanogenic activity (High school): realization and interpretation of the test results.

Re-publication of an article by Mario A. Rosé on Agronotizie

In Part I of this article we have illustrated how the biological activity of an inoculum is measured by introducing a certain amount of reference substrate into a test reactor and verifying that for each gram of COD (Chemical oxygen demand) are produced at least 350 Ncm3 of methane.

Let's analyze in this Part II of article le peculiarities of the test of Specific Methanogenic Activity (High school).

How to carry out the SMA test in practice

The scientific literature on the evidence High school it is very varied as regards the substrates to be used (Ref.[i]).

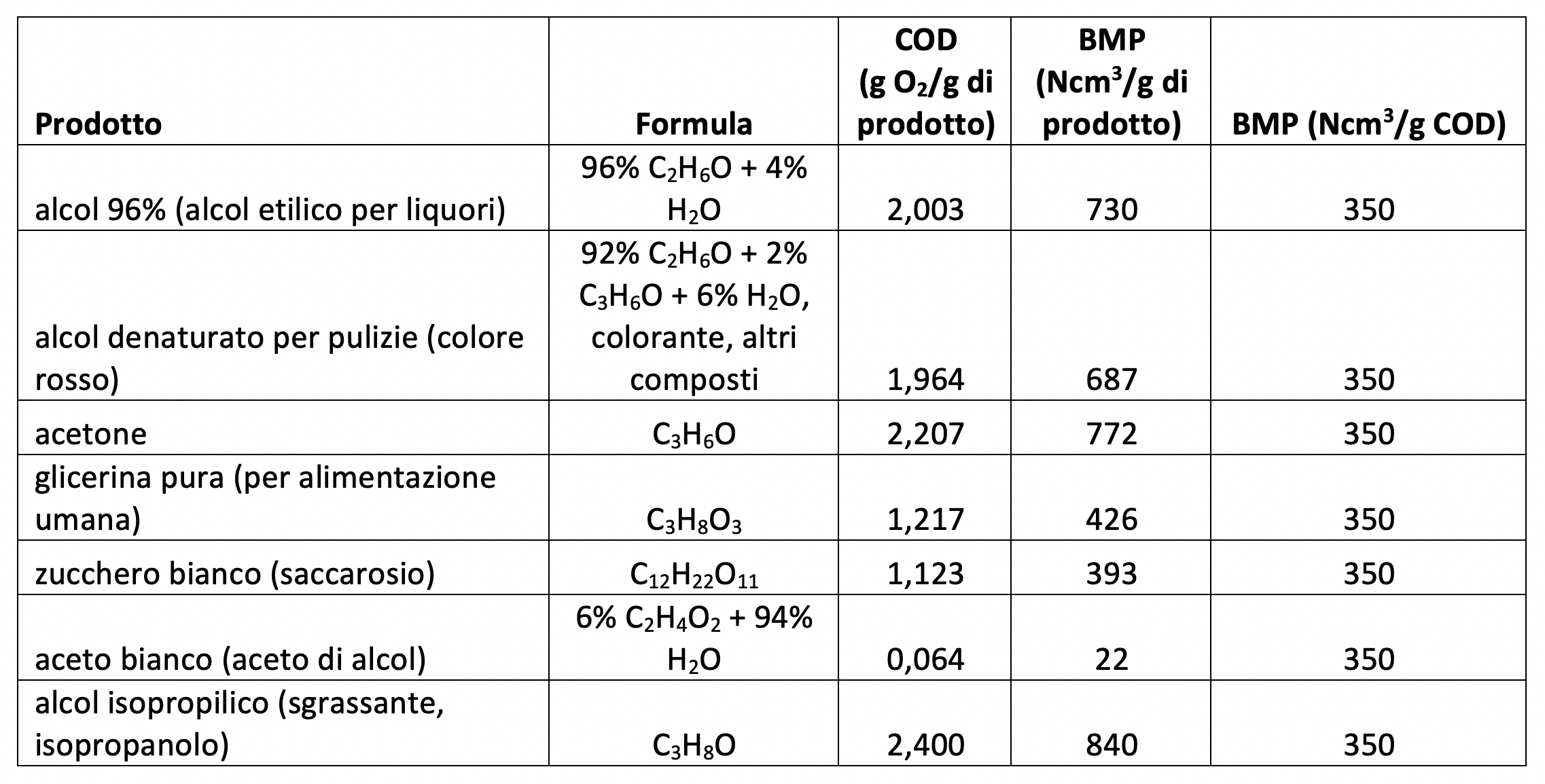

The first doubt that the beginner must resolve before starting a test of methanogenic activity is therefore: which substrate should be used? Generally speaking, any substrate 100% digestible will produce 350 Ncm3 CH4/gCOD, as the Table 1.

From a formal point of view, But, a test carried out with a substrate that is not sodium acetate or acetic acid is certainly a test of biological activity, but a specific test of methanogenic activity cannot be considered. For example, a test carried out with sugar instead of acetate will involve two groups of microorganisms: fermentative bacteria, which will convert the sugar into acetic acid, and the Archaea, which will convert the acetic acid into methane and carbon dioxide. If the test gives a negative result: how can we say with certainty which of the two groups of microorganisms is the one missing or inhibited?

The second aspect to consider concerns the quantity of acetic acid or sodium acetate to be introduced into the test reactor. The ruleUNI / TS 11703:2018 recommends carrying out a positive control in parallel with each Bmp test to ascertain the quality of the inoculum. However, the norm does not establish what the inoculation ratio is: substrate (I/S) to be adopted, implying that it must be “greater than 2” as for any Bmp test. In the particular case of acetic acid, however, the I / S ratio should be much greater than 10, otherwise there is a risk of lowering the pH too much, and also the reaction of the acid with the carbonates and bicarbonates present in the inoculum will produce abundant foam, until the reactor overflows. Sodium acetate, instead, it does not alter the pH of the inoculum because it is a salt, but an I / S ratio too close to 2 It may cause “false negatives” because sodium is an inhibitor of Archaea, as we have already demonstrated in another article in this column (The electrical conductivity is unreliable for the management of the biogas plant).

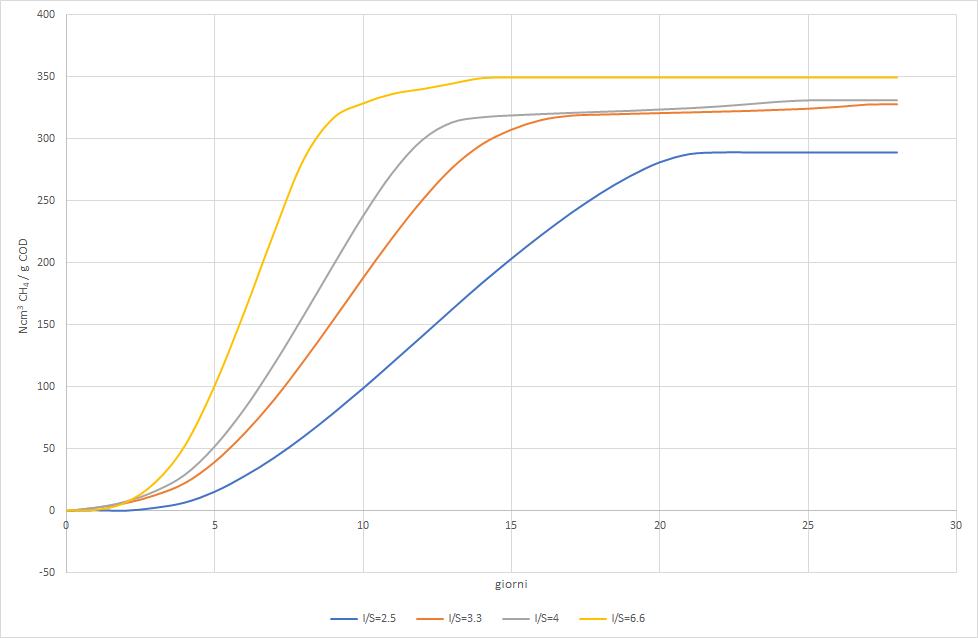

The Photo 1 shows the example of a test carried out on the same inoculum sample, with different amounts of sodium acetate.

Click on the image to enlarge

To practical effects, the evidence of methanogenic activity it must be made with a dosage of sodium acetate – or acetic acid – low enough not to trigger “false negatives” due to the inhibitory effect of these substrates. To avoid the “false negatives”, the sodium acetate dosage should never exceed the inhibition threshold. The scientific literature it is not unique on what this threshold value is. There are values ranging from 7 g of acetate / l of inoculum (Ref.[i]), al range 4-8 g / l valid if – as often happens in agricultural biogas plants– the inoculum has pH> 7,5 (Ref.[ii]) up to a minimum of 2 g /l (Ref.[iii]). It should be noted that all the experiences indicated above refer to digestate from sewage treatment plants, the author has achieved good results with acetate concentrations up to 12 g / l of inoculum. For tests with digestates from agricultural plants, it therefore seems reasonable to assume a limit equal to 10 g of acetate / l of agricultural digestate. If you use acetic acid instead, the total concentration should not exceed i 2,4 g / l of inoculum, otherwise you risk lowering the pH too much (Ref. [iv]). If you don't have pure acetic acid, this concentration is reached with 40 ml of vinegar / l of inoculum(the vinegar contains about 6% of acetic acid by volume).

The unit of measurement of High school

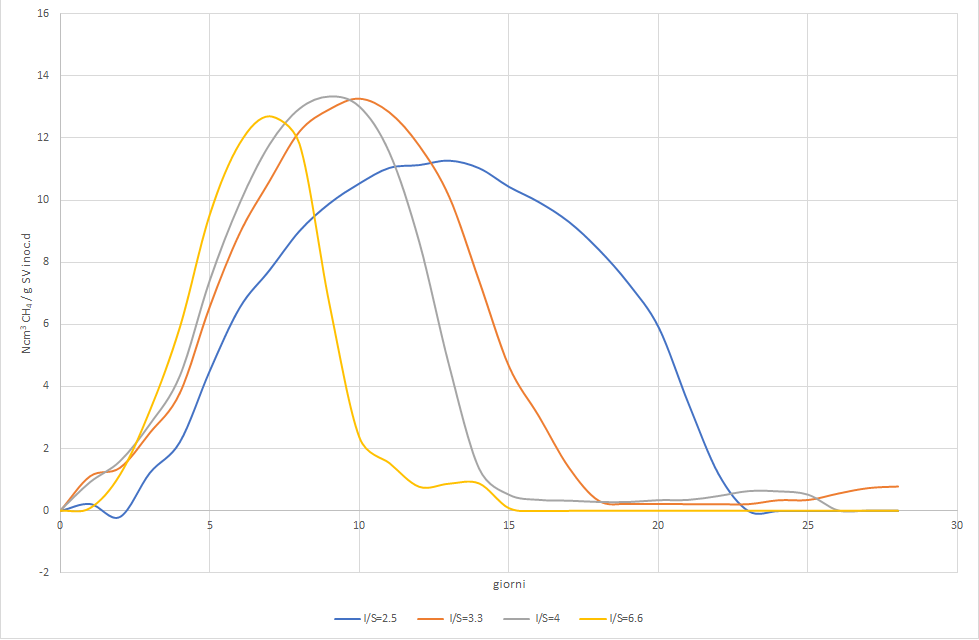

The respiratory rate of any living being is expressed in Nm3 of gas per unit of live weight, per unit of time. In the case of a digestate, the mass of bacteria is represented by volatile solids (SV), usually expressed in g / liter. The methanogenic activity curve is plotted by plotting on the Y axis the daily flow rate of methane per unit of volatile solids in the inoculum, as a function of time, on the X axis. The SMA is the numerical value that corresponds to the peak of this curve, usually expressed in Ncm3 at CH4 / (g SVinoculation x day).

The Photo 2 shows the methanogenic activity curves corresponding to the same test shown in Photo 1.

In general, a value of SMA > 10 Ncm3/g SV . d considers himself good.

Click on the image to enlarge

A real case study

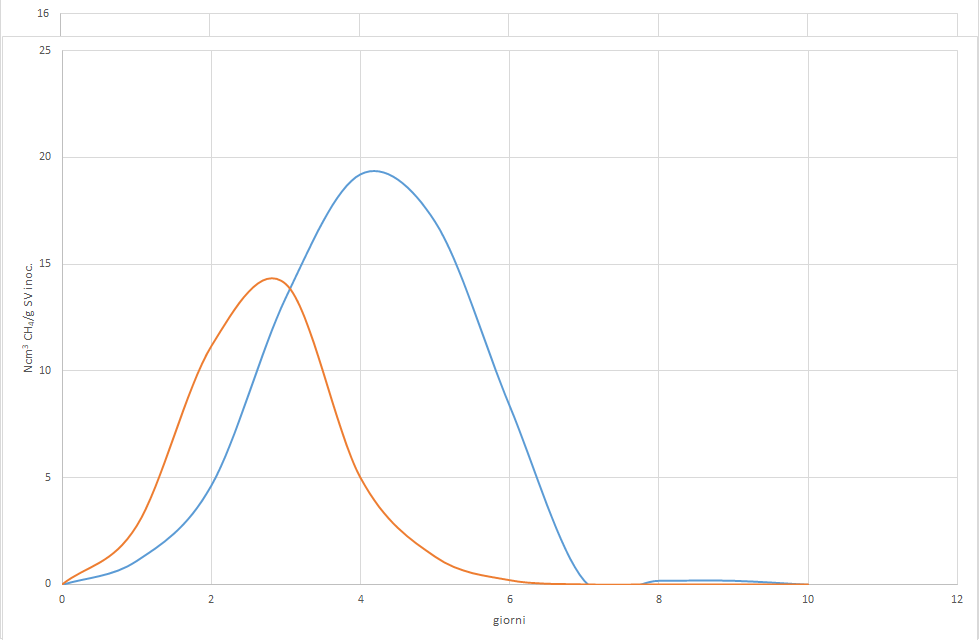

A biogas plant requires a restart following extraordinary maintenance. In the area there are two plants from which the inoculum could be taken, at different distances. The cost of transporting the inoculum from plant A is 3,65 euro / ton and that from plant B is 4 euro / ton. The SMA of the inocula are those indicated in Photo 3. Let's analyze which of the two inocula should be used.

From a purely biological point of view, the inoculumB is better than’A, but both are still valid, as they have Sma> 10 Ncm3/g SVinoc . d while the specific costs are different (inoculum A: 3,65 euro/14 = 0,26 euro per unit of SMA and B inoculum: 4 euro/18 = 0,22 euro per unit of SMA).

On criterion general starts from a assumption: if the amount of inoculum required to start the plant is directly proportional to the biological activity, then we must check whether it is convenient to use the cheaper inoculum in a larger quantity or a smaller quantity of the more expensive inoculum. In economic terms, it is more convenient to start the plant with inoculum B (blue curve, Photo 3), whose transport is more expensive but, having a greater methanogenic activity, will require a smaller amount.

Click on the image to enlarge

Conclusions

The test of specific methanogenic activity (High school) it's a fairly quick and cheap test: allows you to select the most biologically active inoculum, in order to speed up the start-up of a biogas plant with minimum cost. Its implementation is quite simple, but there is still no rule establishing a univocal procedure. The key to a successful test is to maintain the sodium acetate concentration – or acetic acid– below the inhibition threshold of Archaea, otherwise it could generate gods “false negatives”. Generally speaking, a dosage of 10 g acetate / l inoculum, or 2,4 g acetic acid / l inoculum (equivalent 40 ml of vinegar / l inoculum) it is considered reasonable enough to test anaerobic inocula from agricultural facilities.

Bibliographic references and recommended insights

[i] Athar Hussain, Shashi Kant Dubey; Specific methanogenic activity test for anaerobic degradation of influents; Appl Water Sci (2017) 7:535–542; DOI 10.1007 / s13201-015-0305-z.

[ii] Arjen Rinzema, Jules van Lier, Gatze Lettinga, Sodium inhibition of acetoclastic methanogens in granular sludge from a UASB reactor, Enzyme and microbial technology, Volume 10, Issue 1, 1988, pages 24-32, ISSN 0141-0229.

[iii] Satoshi Fukuzaki, Naomichi Nishio and Shiro Nagai; Kinetics of the methanogenic fermentation of acetate; Applied and environmental microbiology, Oct. 1990, p. 3158-3163 Vol. 56, No. 10.

[iv] Souto, T.F., Not here, S.F., Silva, S.Q. et al.Influence of incubation conditions on the specific methanogenic activity test. Biodegradation 21, 411–424 (2010).

[v] Franke-Whittle IH, Walter A, Ebner C, Insam H.Investigation into the effect of high concentrations of volatile fatty acids in anaerobic digestion on methanogenic communities. Waste Manag. 2014; 34(11):2080-2089.

See also:

M. A. Rosato, S. Stromberg; Quick restart of a biogas plant and micronutrients cost minimization with AMPTS II Light, Application note, Bioprocess control.